SAP Batch Management Functionality and Configuration

by Ashikul Alam

My Batch number was ‘07C’ when I was in college. There were thousands of students at my college, ‘07C’ is the number that defines some particular students only. SAP Batch Management is used for a similar functionality: to identify a material by a unique number that possesses some specified information.

My Batch number was ‘07C’ when I was in college. There were thousands of students at my college, ‘07C’ is the number that defines some particular students only. SAP Batch Management is used for a similar functionality: to identify a material by a unique number that possesses some specified information.

Functional Usage

This functionality is activated in SAP based on the business requirement that products produced and procured need to be identified separately for tracking purposes. Food industries, pharmaceuticals, and chemical industries are a good example where Batch Management needs to be maintained. Tracking a material with a unique Batch number involves several functions in SAP:

- Inventory Management (IM) – To search Batch numbers during material movement into the plant

- Production/Process Order (PO) – To search Batch stock for components when creating/releasing PO

- Sales and Distribution (SD) – Search for Batch during Sales Order processing

- Warehouse Management (WM) – To search specific Batch for a Warehouse

Batch Management Level

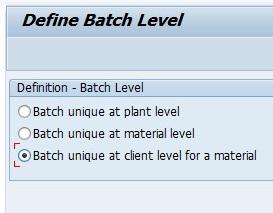

There are three different levels for Bath Management:

Plant Level

At a plant level, a Batch number is unique for a material inside a plant only. The same Batch number can be generated at another plant under the same Company, though these Batches are not the same. If a plant-to-plant stock transfer scenario is used, plant-level Batch numbering is not suitable.

Client Level

In this case, the Batch number is unique for the entire Client, meaning the same Batch number will not be generated for different Plants under the same Company Code. This method is useful when plant-to-plant stock transfer is used, and the Batch number is supposed to be unique.

Material Level

With this method, the Batch number will be unique at the material level only. Thus, in a given plant, different materials can have the same Batch number.

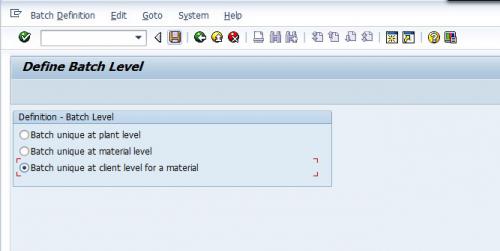

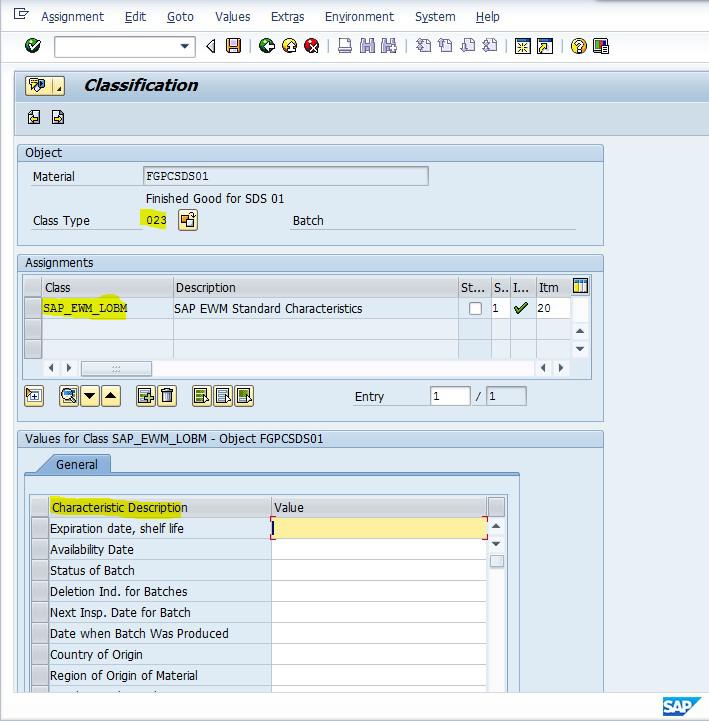

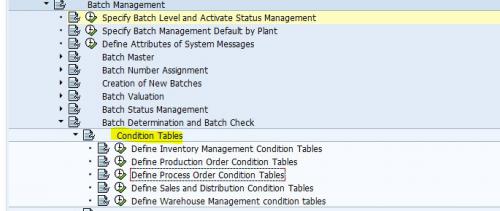

Fig. 1: SAP Batch Level Configuration

Batch Specifications Master Data Structure

Creation of Characteristics

Characteristics can have a fixed value, number range, or can pull values from SAP tables directly. For example, the production date of manufacturing of a produced goods can be found from production order table data, and manual intervention is not required.

During characteristics creation (Tcode CT04), we define how characteristics values will be maintained. Also, characteristics values can be blank so that it can be maintained at a material master classification view later on.

Fig. 2: Material Classification, Class, Class Type, and Characteristics

Creation of Class

All required characteristics are assigned into a Class (Tcode CL01) with class type 023 (Batch Class). In the figure above, ‘SAP_EWM_LOBM’ is the required class that holds all relevant characteristics.

Material Master Maintenance

Finally, the class with assigned characteristics is maintained in the material master classification view (Tcode MM01/MM02). Also, the Batch Management box is ticked in the material master view.

Define Batch Determination

Automatic Batch Determination is used in Inventory Management, Production, Sales & Distribution, and Warehouse Management. It is used to select batches and allocate them in a manufacturing order, an outbound delivery, or a goods issue/good receipt/goods transfer in Inventory Management.

In Production, Sales & Distribution, Inventory Management, or Warehouse Management, the batch determination is used to search and allocate batches for the components in production/process orders. Alternatively, batch determination is used to search and allocate the delivery batches in a customer-based outbound delivery or to search and allocate batches in goods issues.

Create Batch Determination Condition Technique

Once Batch determination condition tables have been created, they become the key combination fields for searching batches. Eventually, the condition records or search strategies are created as master data based on these key combinations. The Condition Tables are created separately for IM, Production, WM, and Sales.

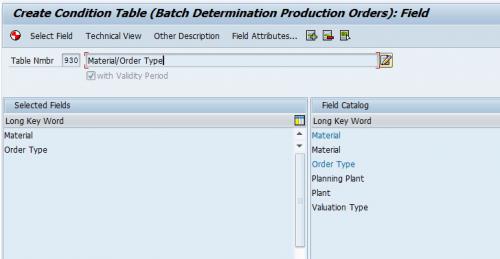

Fig. 3: Different Menu Path for IM, PO, SD, and WM Relevant Condition Table

Fig. 4: Batch Condition Table for Production Order

Create Batch Determination Access Sequence

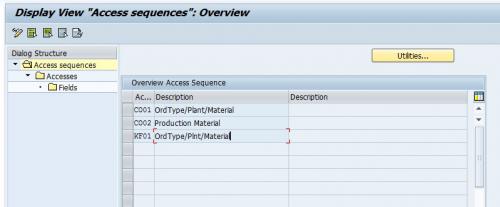

Batch determination access sequences have multiple condition tables (key combinations) assigned in a sequence of priority. This facility allows you to create data for many key combinations so that even if the batch search fails on the first key combination condition, the rest in the priority will help in the search. The Access Sequences are created separately for IM, Production, WM, and Sales. The below screenshot shows all the screens involved in the access sequence configuration.

Fig. 5: Batch Access Sequence

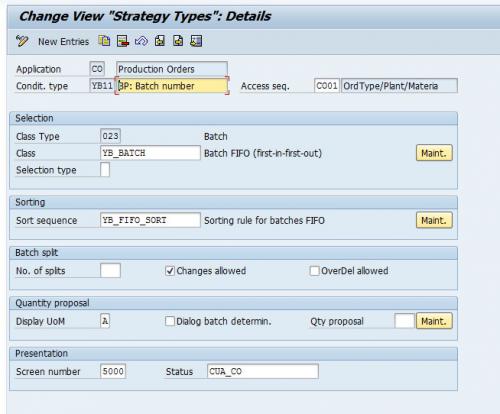

Create Batch Strategy Types

A Batch Search Strategy contains multiple access sequences, though not assigned in any sequential priority. The assignment of the strategy types is done separately for IM, Production, WM, and Sales. The strategy types or condition types are assigned in priority in the next step called “Batch Search Procedure Definition.”

A Batch search strategy is used to search batches using specific rules because you want to automate the process and do not want it to do it manually for every Batch. Thus, you have to aid the system in putting in a decision such as - search all the batches of a given plant, search all batches of a given set of materials within a plant, or search batches for a given component.

Fig. 6: Batch Strategy Types

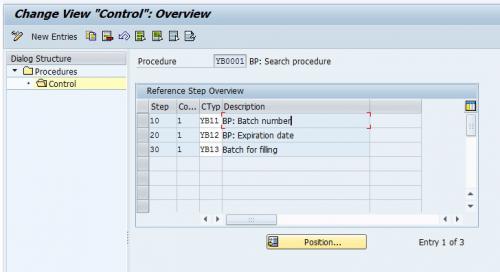

Create Batch Search Procedure

A Batch Search procedure contains multiple strategy types assigned in sequential priority. The Batch search procedure thus becomes the final configuration, which includes the total search configuration together. As before, the Batch Search Procedures are created separately for IM, Production, WM, and Sales.

Fig. 7: Batch Search Procedure

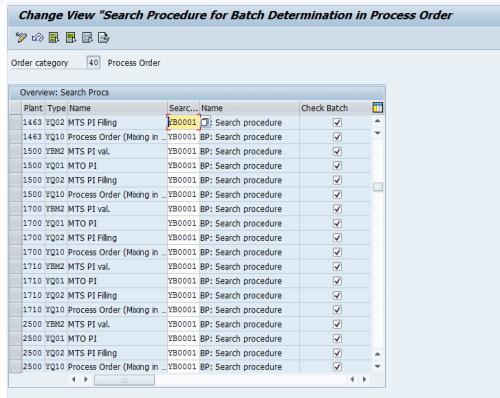

Batch Search Procedure Allocation and Check Activation

In this step, we allocate the batch search procedure to the respective modules. In the case of Inventory Management, the Batch search procedures are assigned to the Movement types. In the case of Production or process orders, the batch search procedures are attached to the production plants and order types.

For the Sales & Distribution module, the Batch Search Procedures are assigned to the Sales Areas and Sales document type. And finally, for Warehouse Management, the Batch Search procedures are attached to the Warehouse number and can also be assigned to the warehouse number + Movement type combination.

Fig. 8: Production/Process Order Batch search procedure allocation via plants and order types

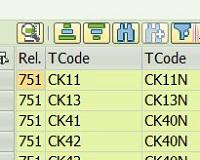

After completing the entire configuration, the Batch search condition record can be generated using these SAP transaction codes:

- For Inventory Management: MBC1 – Create, MBC2 – Change, MBC3 – Display

- For Production Order/Process Order: COB1 – Create, COB2 – Change, COB3 – Display

- For Sales & Distribution: VCH1 – Create, VCH2 – Change, VCH3 – Display

- For Warehouse Management: LS51 – Create, LS52 – Change, LS53 – Display

by Ashikul Alam

More Blogs by Ashikul Alam

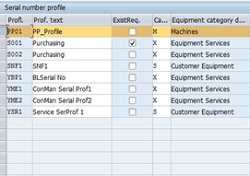

SAP Serial Number Functionality and Configuration

The first feature that comes to mind while writing about the serial nu...

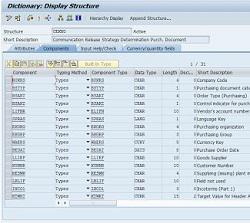

SAP Purchase Order (PO) Release Strategy Configuration

When we spend the company's money, we require the necessary approv...

Related Blogs

How to find obsolete transactions in S/4HANA

Many transactions have been deprecated in SAP S/4HANA from ERP6.0. In ...

.png)